Plastic Pinion Gear Manufacturing Efficiency

Introduction to Plastic Pinion Gear Manufacturing Efficiency

Plastic pinion gear manufacturing efficiency plays a crucial role in the production of high-quality plastic pinion gears. It involves optimizing the manufacturing processes to ensure maximum productivity, cost-effectiveness, and quality. By enhancing efficiency, manufacturers can meet the growing demand for plastic pinion gears in various industries.

Connection between Plastic Pinion Gear Manufacturing Efficiency and Informational

Efficient plastic pinion gear manufacturing relies heavily on accurate and comprehensive informational. Manufacturers must gather data on material properties, gear design, production techniques, and quality control measures. This information enables them to streamline manufacturing processes, reduce errors, and enhance overall efficiency.

Performance Characteristics of Plastic Pinion Gear

Plastic pinion gears offer several key performance characteristics:

- High durability and impact resistance

- Low noise and vibration levels

- Excellent corrosion resistance

- Precise and smooth operation

- Wide range of temperature tolerance

Types of Plastic Pinion Gear and Their Advantages

There are various types of plastic pinion gears available, each with its unique advantages:

- Acetal Pinion Gears: Known for their high strength and low friction properties.

- Nylon Pinion Gears: Offer excellent wear resistance and self-lubricating properties.

- Polyphenylene Sulfide (PPS) Pinion Gears: Known for their superior chemical and heat resistance.

- Polycarbonate Pinion Gears: Provide exceptional impact resistance and transparency.

Applications of Plastic Pinion Gear in Various Industries

Plastic pinion gears find extensive applications in different industries:

- Consumer Electronics: Used in printers, scanners, and digital cameras for precise movement.

- Agricultural Machinery: Enable efficient power transmission in farming equipment.

- Automotive Industry: Used in steering systems, windshield wipers, and power windows.

- Medical Devices: Essential components in medical imaging equipment and surgical instruments.

- Aerospace: Used in aircraft controls, navigation systems, and satellite mechanisms.

Future Trends and Opportunities for Plastic Pinion Gear Products

The plastic pinion gear industry is expected to witness significant growth and opportunities in the future. Some key trends include:

- Increasing demand for lightweight and durable plastic gear solutions.

- Rapid advancements in manufacturing techniques, such as 3D printing.

- Growing focus on sustainability and eco-friendly gear materials.

- Expanding applications in emerging industries, such as renewable energy.

- Continuous improvements in gear design and efficiency.

Choosing the Right Plastic Pinion Gear

To select the correct plastic pinion gear, consider the following factors:

- Clearly define your gear requirements based on load capacity, speed, and operating conditions.

- Choose the appropriate material based on factors such as chemical resistance and temperature range.

- Optimize gear design for efficient power transmission and minimal friction.

- Select reliable suppliers with a proven track record in plastic gear manufacturing.

- Consider the overall cost-effectiveness and the availability of post-sales support.

Maintenance of Plastic Pinion Gear

Maintaining plastic pinion gears is essential for their longevity and performance. Follow these guidelines:

- Regularly inspect the gear for any signs of wear, damage, or misalignment.

- Clean and protect the gear from corrosion using appropriate techniques and coatings.

- Ensure proper lubrication and perform regular maintenance to prevent excessive wear.

- Replace worn-out components promptly to avoid further damage or performance issues.

- Continuously improve and upgrade gear designs to optimize performance and reliability.

Why Choose Us

When it comes to plastic pinion gears, our company stands out for several reasons:

- High-Quality Products: We manufacture plastic pinion gears that meet stringent quality standards.

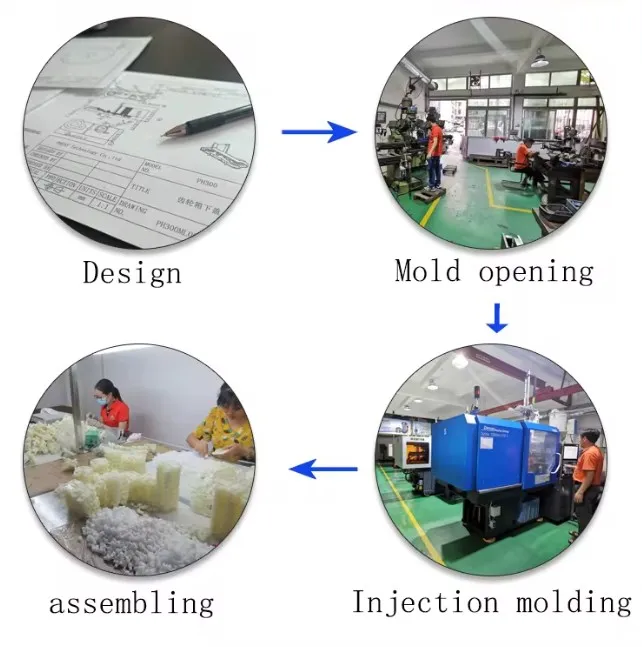

- Advanced Manufacturing Techniques: Our state-of-the-art facilities ensure efficient production processes and precise gear manufacturing.

- Customization Options: We offer flexible design and material options to meet specific customer requirements.

- Expertise and Experience: Our team of professionals has extensive knowledge and experience in plastic gear manufacturing.

- Dedicated Customer Support: We provide excellent pre- and post-sales support to ensure customer satisfaction.

Q&A

- Q: Can plastic pinion gears handle heavy loads?

A: Yes, plastic pinion gears can handle heavy loads due to their high durability and strength properties. - Q: Are plastic pinion gears suitable for high-speed applications?

A: Yes, plastic pinion gears can be designed and manufactured for high-speed applications, provided the appropriate material and design considerations are taken into account. - Q: Are plastic pinion gears resistant to chemicals?

A: Yes, depending on the material, plastic pinion gears can exhibit excellent chemical resistance. - Q: Can plastic pinion gears be used in extreme temperature conditions?

A: Yes, certain types of plastic pinion gears, such as those made from Polyphenylene Sulfide (PPS), offer excellent heat resistance and can withstand extreme temperatures. - Q: How long do plastic pinion gears typically last?

A: The lifespan of plastic pinion gears depends on various factors such as operating conditions, maintenance practices, and load requirements. With proper care and maintenance, they can have a long service life.

Author: Dream